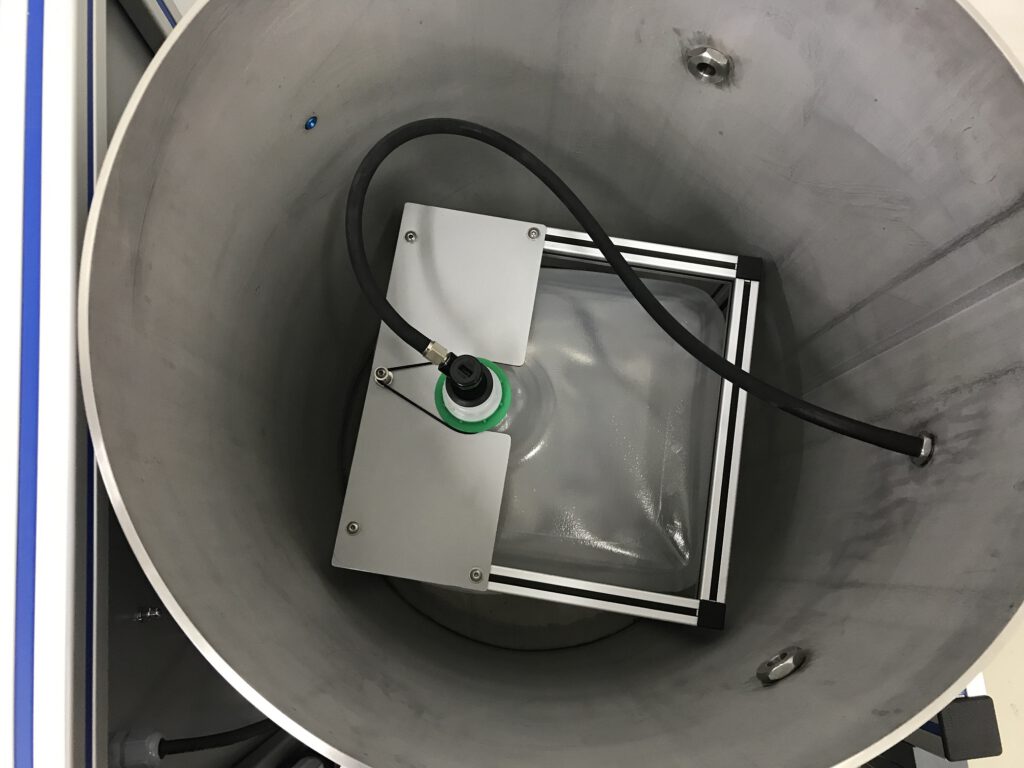

Bulk Degasser

Ink degassing machine

One of the most challenging problems when filling inkjet cartridges is that the ink cannot reach the spaces filled with air. Therefore, our filling technology evacuates the empty cartridges before filling the ink into them. Another problem occurs when ink enters the evacuated area. A pressure balance takes place at atmospheric pressure, which lets fluids absorb more or less air. The balance turns, and the air escapes the liquids in a vacuum immediately. The phenomenon is a disadvantage during the cartridge filling because the escaping air fills the priorly evacuated spaces and hinders the smooth extension of the ink. We can significantly reduce this negative effect when using degassed ink. As a result, we decided to design an ink degassing machine

Machine description

The bulk degassing takes place in a collapsing container. We seal the container air-free and airtight after the degassing. The container remains air-free during the entire time of emptying through the cartridge filling. The bulk degassing has a stirring that changes the ink surface during the degassing permanently. The degassing is complete when the desired pressure level inside the container reaches, and the air escape finishes. During the automatic cycle, the bulk degassing machine doesn’t need a particular operation. It signalizes with sound signals the end of degassing. When the degassing is complete, you can easily connect the prepared ink container to the filling machines.

Advantages and disadvantages

- Usable for FDA applications without limitations.

- The bulk degassing is a favorable option if you expect frequently changing small ink batches (up to 2000 cartridges).

- You can clean and reuse the collapsing containers a few times that increase economic efficiency.

- The bulk degassing procedure requires more skills from the operator than an inline degassing.

Benefits of ink degassing

A bulk degasser is a stand-alone machine, and you can combine it with any of our filling machines. Degassed ink extends the possible shelf time of cartridges. It enables you to prepare ready inks before the filling process so that you can plan your degassing production independent of cartridge filling. You can also test the ink behavior after degassing and test your ink as a degassed product